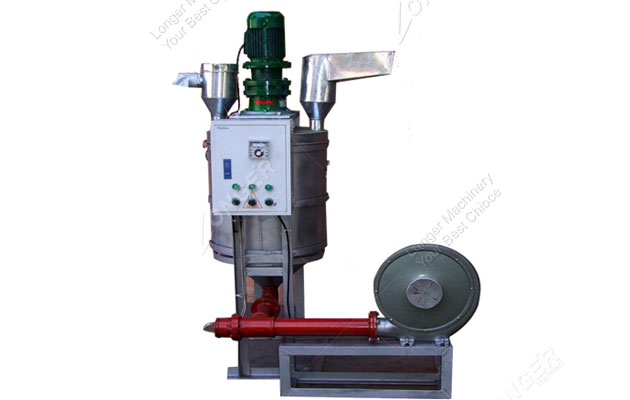

Fish Pellet Drying Machine With High Efficient

Application:It is used for drying the finished fodder pellet,so as to make the fodder can keep long time.

Raw Material:feed

Capacity:25-400kg/h

Loading Porting:Shanghai Port/Qingdao Port

Voltage:50HZ/220-380V

Product Induction:

1) The dryer machine with PID temperature control, accurate and reliable temperature control.

2) Curved design of hot air tube to avoid burning caused by the accumulation of scraps at the bottom of the tube.

3) Thermal diffusion device used to evenly disperse hot air, keeping the drying temperature of the plastic even, improving drying efficiency.

4) Barrel and hopper are separate for easy material cleaning and fast material change.

5) Barrel can be turned over on the hopper for fast material change and easy maintenance.

6) Over temperature protection device installed. It will shut down once there is over heat.

7) Windows on the body and base of the barrel for observation of the material inside

8) Work with 24-hour Panasonic timer with pre-configured switch.

9) Double insulation barrel is optional for all machine types

Advantages:

1. New generation of standard hot air dryer, improved functions as to be more

environment concern;

2. Energy saving. Decreasing heat lost by recycling, save electricity greatly;

3. Improved efficiency concentration of thermal energy, dehumidification facilities able

to expel moisture rapidly, speed drying;

4. Environment cleaning. Airtight design, able to filter out powder material during drying circle, eliminate contamination, decrease high temperature of working environment brought by drying;

5. Special filter to withstand 150 degree high temperature blower assuring safe operation.

1) The dryer machine with PID temperature control, accurate and reliable temperature control.

2) Curved design of hot air tube to avoid burning caused by the accumulation of scraps at the bottom of the tube.

3) Thermal diffusion device used to evenly disperse hot air, keeping the drying temperature of the plastic even, improving drying efficiency.

4) Barrel and hopper are separate for easy material cleaning and fast material change.

5) Barrel can be turned over on the hopper for fast material change and easy maintenance.

6) Over temperature protection device installed. It will shut down once there is over heat.

7) Windows on the body and base of the barrel for observation of the material inside

8) Work with 24-hour Panasonic timer with pre-configured switch.

9) Double insulation barrel is optional for all machine types

Advantages:

1. New generation of standard hot air dryer, improved functions as to be more

environment concern;

2. Energy saving. Decreasing heat lost by recycling, save electricity greatly;

3. Improved efficiency concentration of thermal energy, dehumidification facilities able

to expel moisture rapidly, speed drying;

4. Environment cleaning. Airtight design, able to filter out powder material during drying circle, eliminate contamination, decrease high temperature of working environment brought by drying;

5. Special filter to withstand 150 degree high temperature blower assuring safe operation.